G-O-METRIC, INC. is the worlds premiere manufacturer of RFI/EMI Honeycomb Ventilation Panels.

We have been manufacturing these panels for over 40 years and serve government, military, medical, and a wide variety of electronics service industries.

As the electromagnetic spectrum becomes more and more crowded with frequencies generated by everything from cordless telephones to sophisicated phased array radars, engineers must increasingly face the task of maintaining the RFI/EMI integrity of the shielded enclosure.

This fact, coupled with the ever increasing heat removal requirements of today's dense electronics packaging designs, makes choosing the right shielded ventilation panel more important than ever before. By selecting carefully from the available sizes, the engineer can meet the shielding effectiveness requirement, as well as other design criteria, while keeping costs down.

G-O-Metric, Inc. is a custom manufacturer, providing the engineer with a complete line of honeycomb panels from which to choose. Brass or steel honeycomb is available in a wide range of combinations of cell sizes and depths.

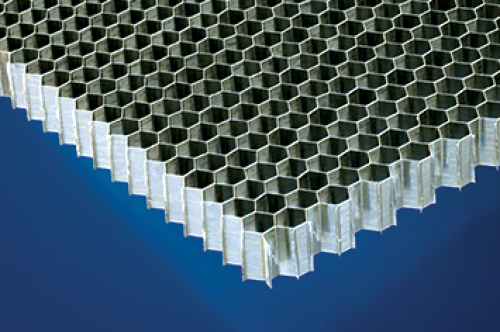

As a custom manufacturer, we can provide our honeycomb in a variety of mounting frames. The angle style provides a mounting flange of appropriate width and a secure mounting for the honeycomb inside the frame. The honeycomb is soldered continuously on both top and bottom. This superior method yields a mechanically strong mount, as well as unsurpassed continuity between honeycomb and frame. The standard 1 /8" recess lends to the overall appearance of the panel and provides a degree of protection for the face of the honeycomb when installed. This combination of reliability and simplicity makes the angle frame the most commonly asked for frame style.

The C-Channel frame style provides a very secure and attractive means of attachment to the shielded enclosure. And, because our honeycomb is continuously soldered to the frame on both sides, outstanding continuity and rigidity is achieved. Our panels are not subject to the corrosion and vibration induced problems that plague "crimp" style C-Channel frames that rely on a "tooth" that bites into the honeycomb core for continuity. Instead, a metallurgical bond between honeycomb and frame makes this one of the most reliable methods available. Through-holes or captive fasteners make installation a breeze.

MATERIALS

All raw materials are inspected upon delivery and certified to meet or exceed the following specifications:

• Brass Alloy C260 Half Hard

- ASTM B36

• Steel

- SAE-1008

• Solder

- ASTM B32

GASKET

Insuring the RFI/EMI integrity of the critical mating surfaces between

the shielded enclosure and the honeycomb panel calls for the selection of the proper gasket. We offer a complete line of gasket materials and configurations to complement our honeycomb panels.

FINISH

Finishes are available in a wide selection to enable the engineer to match his corrosion resistance requirements with the most cost effective finish. Tin plating in accordance with MIL-10727

(ASTM B545) is perhaps the most common selection. Other possibilities include nickel plating and painting.

Size Options

| Cell Width by Cell Depth | Cell Width by Cell Depth | Cell Width by Cell Depth |

|---|---|---|

| 1/8" by 1/4" | 3/16" by 1/2" | 1/4" by 1/2" |

| 1/8" by 3/8" | 3/16" by 5/8" | 1/4" by 5/8" |

| 1/8" by 1/2" | 3/16" by 3/4" | 1/4" by 3/4" |

| 1/8" by 5/8" | 3/16" by 1" | 1/4" by 1" |

| 1/8" by 3/4" | ||

| 1/8" by 1" |